86-139-1681-7899

Belonging category: Powder Packing Machine

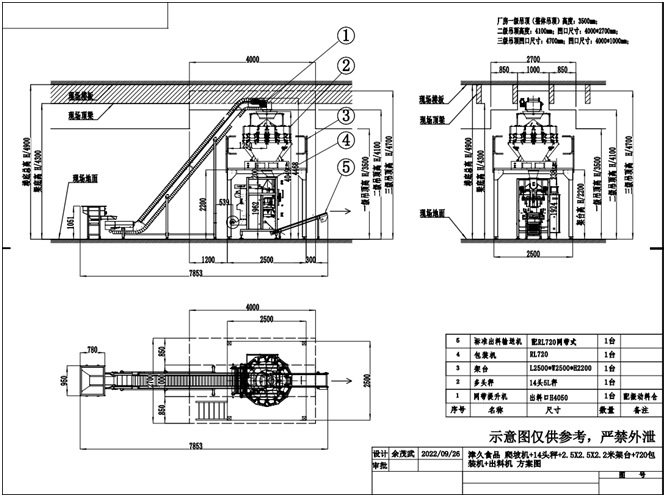

Product Introduction: Automatic Granule Bags 100--3000grams Filling Line TechnicalDocument 3. performance parameters: Bagsizelong150 - 500 mmWidth 150 - 350 mmFilmwidth320- 720mmApplicable packaging film materialOPP/ PE, PVC, OPP/ CPP, PT /PE, KOP/CPP, VMCPPPackingweight …

86-139-1681-7899

86-139-1681-7899

Automatic Granule Bags 100--3000 grams Filling Line

Technical Document

3. performance parameters:

|

Bag size |

long 150 - 500 mm |

|

Width 150 - 350 mm |

|

|

Film width |

320 - 720mm |

|

Applicable packaging film material |

OPP / PE, PVC, OPP/ CPP, PT /PE, KOP/CPP, VMCPP |

|

Packing weight range |

100gr-3000gr. |

|

Packaging speed range |

5-50 bags/minute depending on the material conditions |

|

Packaging speed |

10-40 bags/minute |

|

Power supply type |

220V 50Hz ( or 60Hz) |

|

Compressed air |

6-8Kg/m2,0.15m3/ min |

|

Power consumption |

4 KW |

4. automatic quantitative packaging equipment

(pictures are for reference only, the actual product shall prevail)

|

Packaging machine host |

The pictures are for reference only, please refer to the actual product Equipment features: 1. Equippedwithsafetyprotectiontomeettheenterprisesafetymanagement requirements. 2. Adoptintelligenttemperaturecontroller,accuratetemperaturecontrol,ensuring beautiful and smoothsealing. 3. The PLC servo system, pneumatic control system and ultra-large display touch screenareusedtoformthedrivecontrolcore,whichmaximizesthecontrolaccuracy, reliability and intelligence of the wholemachine. 4. This machine and metering configuration can automatically complete the entire packaging process of metering, feeding, filling and bagging, date printing, inflation (exhaust),andfinishedproducttransportation,andautomaticallycompletecounting. 5. Thetouchscreencanstorepackagingprocessparametersforavarietyofdifferent products,whichcanbeusedatanytimewithoutresettingwhenchangingproducts. 6. Thereisafaultdisplaysystemtohelptroubleshoottheprobleminatimelymanner.

|

|

Multi-angle combination scale |

1. Adopt high-precision, high-standard special sensors, with a resolution of 1 decimalplace 2. Factory parameter setting recovery function, supporting multi-stage weight calibration; 3. It can automatically pause when there is a lack of material, making theweighing more stable; 4. Storing 100 sets of parameter settings to meet various material requirements, with help menu for easy learning anduse; 5. During operation, the amplitude of each line can be adjusted independently to make the feeding moreuniform; 6. Multiplelanguagesareavailable,easytooperate,suitablefortheglobalmarket; 7. A new multi-angle hopper is added, and an adjustable gate is added to each outlettoeffectivelydistributethematerialstothevibrationplatesofeachline; 8.Specially designed deep U- shaped vibration plate to prevent materials from leaking to both sides of the vibrationplate; 9. Unified design standards and mold manufacturing technology make the interchangeability of various partsstronger. 10. Optionalweighingmaterialdetectiontoaccuratelycontrolthefeedingtime and material thickness to ensure weighingaccuracy; 11. The thickened cast aluminum center seat enhances the strength ofthe machine and shortens the weighing stabilizationtime; |

|

Platform |

|

|

Hoist |

|

|

Weight Checker |

The EW series weight sorter is specially designed for high-precision requirements, high stability, and intelligent detection technology for package weight , and has core invention patents . It uses imported famous brand components and integrated circuits, adopts high-precision CNC structure design , and cooperates with patented weighing algorithms and other advanced technologies to achieve industry-leading detection performance. 1. German HBM original gravitysensor 2. Danfoss inverter fromDenmark 3. Japan Omron PhotoelectricSwitch 4. Japanese NTN originalbearings 5. Japanese Bando timingbelt 6. Schneider ElectricComponents 7. AirTac PneumaticComponents 8. 7-inch industrial touchscreen 9. All stainless steel 304rack

|

5.Packaging machine configuration table

content

PLC controller ( Siemens ) including wiring

Touch screen ( Siemens )

Servo motor ( Siemens )

Servo drive ( Siemens )

Thermostat ( OMRON )

Solid State Relay (Schneider)

Circuit breaker ( Siemens )

Paper feeding motor (Beijing Weitewei)

Color code electric eye ( Baideli )

Longitudinal sealed cylinder ( Festo )

Horizontal seal standard cylinder ( Festo )

Servo propulsion standard cylinder ( Festo )

Cutter thin cylinder ( Festo )

Solenoid valve ( Festo )

Paper pulling synchronous belt (own brand)

Bag Maker (All Stainless Steel, Aluminum Alloy)

Next: SNQSF-120 Lab Jet Mill

Take a screenshot and recognize the QR code

MGM Machinery