86-139-1681-7899

Belonging category: Powder Packing Machine

Product Introduction: TheQuotation & Related InstructionNo.Products nameQTY (set)PictureRemark1520 vertical packing machine11. Including heat transfer printing and coding machine2. Including encoder3. Vacuum cleaner4. Including nitrogen charging device5. Powder hopper …

86-139-1681-7899

86-139-1681-7899

SN-520A Lapel type electronic scale

automatic packaging machine

The Quotation & Related Instruction

|

No. |

Products name |

QTY (set) |

Picture |

Remark |

|

1 |

520 vertical packing machine |

1 |

|

1. Including heat transfer printing and coding machine 2. Including encoder 3. Vacuum cleaner 4. Including nitrogen charging device 5. Powder hopper with touch screen 6. Powder hopper with liquid level sensor 7. Includes a collar shaper |

|

2 |

Former |

2 |

|

160mm-520mm |

|

3 |

Auger filler |

1 |

|

1. The capacity is 50L

2. Servo motor control metering

|

|

4 |

Screw conveyor |

1 |

|

1. The capacity of the silo is 200L 2. The silo is designed in a circular shape, making it less prone to dust accumulation |

|

5 |

Finished bag conveyor |

1 |

|

1. Belt type |

|

6 |

Nitrogen generator+cold drying machine (Optional) |

1 |

|

1. Nitrogen generator 2. Image for reference only |

|

|

||||

|

Note: (1)The above quotation is FOB Shanghai price. (2)The contact parts of the equipment and materials are 304 stainless steel or food-grade ABS plastic. (3)Delivery time: The contract is signed and the deposit is received in about 30days. (4)After sales service; The warranty period is one year. |

||||

1,Customer's packing requirements

1.Packaging material: Pesticide powder

2.Packaging weight: 500g

3.Packaging speed: 30-35 bags/min

4.Specific bag type: Back sealed bag

5.Bag size: Bag width 7-25cm

6.Packaging material: Suitable for various heat sealing composite films

7.Specific packaging requirements:

8.Recommended accessories: screw feeder+screw metering machine+520 packaging host+finished product conveyor

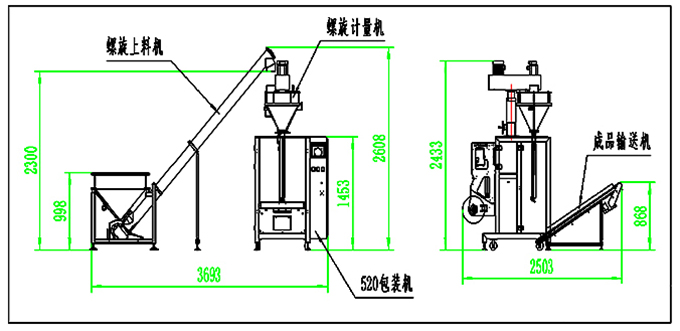

2, Complete set of dimensions and renderings for the fully automatic HMD-520 vertical packaging machine:

The whole process of automatic packaging equipment

Screw feeder automatic feeding→Screw weighing machine automatic weighing→Unloading to the packaging machine for automatic packaging→Finished product conveyor transport bag to the packaging platform

4、Complete set of parameters for the fully automatic SN-HMD-520 vertical packaging machine:

|

Item |

Content |

|

Capacity |

Within 20-60 bags/min,depending on the measuring equipment,materials & packing film’ material. |

|

Accuracy |

*≤±1.% , depending on the measuring equipment & materials |

|

Bag size |

(L)80-350 mm (W)70-250 mm |

|

Film width |

Max 520mm |

|

Bag type |

Pillow style bag, packaging material using roll film, machine automatically makes bags with top and bottom sealing and back sealing |

|

Film thickness |

0.04-0.09mm |

|

Package material |

BOPP/VMCPP,PET/PE,BOPP/CPP, PET/AL/PE etc |

|

Air consumption |

0.8ps 0.25m3/min |

|

Total powder |

7.5KW |

|

Air compressor |

Not less than 1 CBM |

|

voltage |

Three phase four wire 380V 50HZ |

|

Total height of the entire set of equipment |

2.608M |

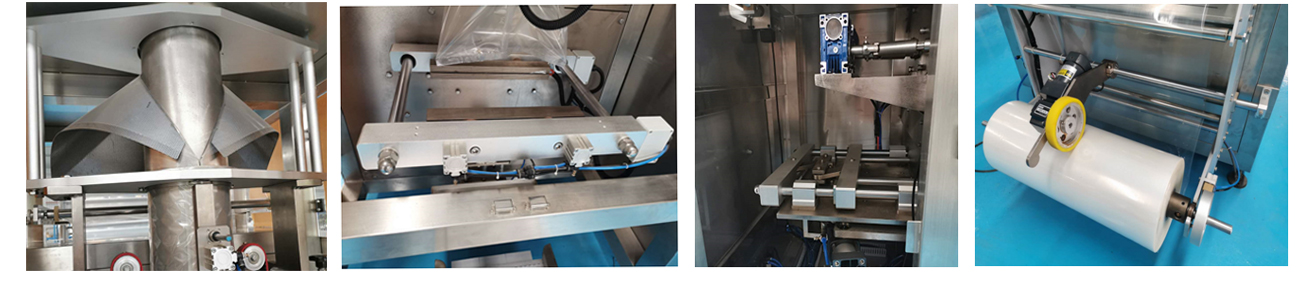

3. Introduction and detailed diagram of HMD-520 vertical packaging host:

(1) Functional characteristics of SN-HMD-520 packaging host:

Brief introduction

* The whole machine is advanced in design, reasonable in structure, convenient in adjustment, operation and maintenance.

* Servo film transport system positioning standard; synchronous film transport, stable and reliable;

* The automatic correction function saves time and film, and improves the reliability and intellectualization of the whole machine.

* It has a variety of automatic alarm and protection functions to minimize loss.

* This machine is matched with metering device, and automatically completes the whole process of product metering, feeding, filling and bagging, printing date, inflating (exhausting), and finished product output.

Technical parameter

|

Items |

Content |

|

Packing speed |

Max 30-60 bags/min ( for empty bag making) |

|

Bag size |

(L)80-350 mm (W)70-250 mm |

|

Bag making mode |

Back sealing bag, corner standing bag, punching device |

|

film thickness |

0.04-0.09mm |

|

Gas consumption |

0.8ps 0.3m3/min |

|

Air consumption |

0.8 Mpa 0.3 cmb/min |

|

Power source |

3KW 220V/380V 50Hz/60Hz |

|

Dimension |

(L)1480×(W)1130×(H)1450mm |

|

The weight of switchboard |

480 kg |

|

No |

Electronic Part |

Brand |

Original |

|

1 |

Programmable Logic Controller (PLC) |

SIMENS |

Germany |

|

2 |

touch screen |

SIMENS |

Germany |

|

3 |

Servo motor+servo drive |

SIMENS |

Germany |

|

4 |

Horizontal sealing cylinder |

AIRTAC |

Taiwan |

|

5 |

Vertical sealing cylinder |

AIRTAC |

Taiwan |

|

6 |

Knife cutting cylinder |

AIRTAC |

Taiwan |

|

7 |

solenoid valve |

AIRTAC |

Taiwan |

|

8 |

Intermediate relay |

OMRON |

Japan |

|

9 |

Power switch |

MEAN WELL |

China |

|

10 |

Temperature control meter |

YATAI |

China |

|

11 |

Solid state relay |

SCHNEIDER |

France |

|

12 |

Paper color coded electric eye |

OETAI |

China |

|

13 |

Leakage switch |

TANGENT |

China |

|

14 |

Circuit breaker |

TANGENT |

China |

|

15 |

Vertical sealing heating tube |

BAOSHENG |

China |

|

16 |

Horizontal sealing heating tube |

BAOSHENG |

China |

|

17 |

thermocouple |

BAOSHENG |

China |

|

18 |

Film release motor |

GPG |

China |

|

19 |

Correction moto |

GPG |

China |

|

20 |

Pulling film reducer |

GPG |

China |

|

21 |

Ribbon coding machine |

DINGSHENG |

China |

|

22 |

Proximity switch |

SINO |

China |

|

23 |

wire |

SINO |

China |

|

24 |

Whole machine bearings |

SINO |

China |

|

25 |

Stainless steel screws |

SINO |

China |

|

26 |

Roll film inflation shaft |

KEDA |

China |

|

27 |

Pulling film belt |

BAOLEI |

China |

|

28 |

Pulling film box coupling device |

EST |

China |

5.Description and information of auger filler

|

Item |

Large-size auger filler |

|

Weight range |

5-3000g |

|

Speed |

Max50bags/min |

|

Accuracy |

±0.3-1.5% |

|

Power |

380V 2.5KW |

|

External dimensions |

L690*1030*H1100mm |

|

Weight |

150kg |

|

measuring method |

Spiral rotating filling type |

6.Description and information of screw conveyor

Feature

This conveyor is suitable for multiple powdery product. Working together with packing machine, the product feeding of the conveyor is controlled to retain the product level in the product cabinet. And the machine can be used independently. All parts are made of stainless steel except the electric motor, bearing and support frame.

Parameter

|

Conveying capacity |

1-10 (ton/hour) |

|

Lifting height |

3m-20m |

|

Lifting capacity |

3 cubic metre/hour |

|

Size |

Can be customized |

|

Material |

Contact parts with products is 316 S/S |

|

Power |

750W |

7.Description and information of finished bag conveyor

Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

Parameter

|

Belt width |

300mm |

|

Lifting height |

0.8m~0.9m |

|

Feeding speed |

300mm\minute |

|

Dimension |

1013mm(H)×410mm(L)×900mm(Lifting height) |

|

Voltage |

220V/50W |

|

weight |

50kg |

|

No. |

Name |

For free Quantity |

Remark |

|

1 |

Horizontal heater |

4pc |

|

|

2 |

Vertical heater |

2pc |

|

|

3 |

Pulling belt |

2pc |

|

|

4 |

Teflon tape |

1pc |

|

|

5 |

T type cutter |

2pc |

|

|

6 |

Thermocouple |

2pc |

|

|

7 |

Allen wrench |

1pc |

|

|

8 |

Monkey wrench |

1pc |

|

|

9 |

Copper brush |

1pc |

|

Take a screenshot and recognize the QR code

MGM Machinery