86-139-1681-7899

Belonging category: Powder Packing Machine

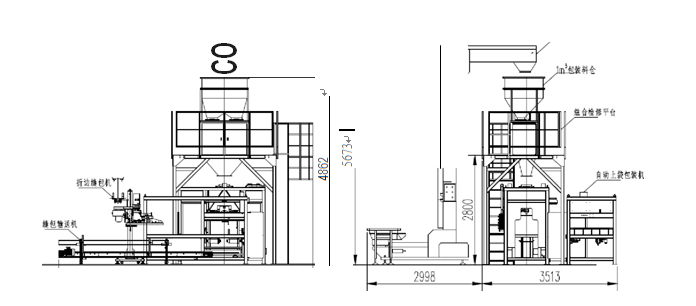

Product Introduction: AutomaticGranule Bags 10 KGs Filling Line Technical Document2.1 ,Design parameters of pesticide granule automatic packaging systemSystem NamePesticide Granules Fully AutomaticPackaging SystemProduct NamePesticide particlesSystem TypeAutomatic bagging …

86-139-1681-7899

86-139-1681-7899

Automatic Granule Bags 10 KGs Filling Line

Technical Document

|

System Name |

Pesticide Granules Fully Automatic Packaging System |

|

|

Product Name |

Pesticide particles |

|

|

System Type |

Automatic bagging + automatic sealing + conveying |

|

|

Physical properties |

form |

Granular columnar |

|

temperature |

Normal temperature |

|

|

Bulk density |

~ 0.5-0.7 t/m3 |

|

|

Popularity |

good |

|

|

Corrosive |

have |

|

|

Dangerous explosion |

have |

|

|

Packaging Capabilities |

Packing Specifications |

1 0kg/bag inner film bag |

|

Bag Type |

For M bag, the inner bag and outer bag openings must fit together |

|

|

Bag size W*H |

(420mm+80mm)*700mm |

|

|

Packaging output |

450 bag/h (guaranteed value) |

|

|

Weighing capacity |

Measuring accuracy |

±0.2-0.3% |

|

Metering capability |

50 0 bag/h (guaranteed value) |

|

|

Palletizing capacity |

Palletizing type |

Manual palletizing |

|

Stomp structure |

/ |

|

|

Palletizing capacity |

/ |

|

|

Work Environment |

indoor-10℃-40℃ |

|

2.2 Main technical requirements for granular pesticide packaging system

|

Serial |

name |

Subcontractors |

|

1 |

Motor |

ABB Motor (explosion-proof) |

|

2 |

Circuit breakers, contactors,thermal protectors, relays and |

Schneider |

|

3 |

Frequency Converter |

Schneider |

|

4 |

Weighing Instrument |

Shenzhen German Technology |

|

5 |

touchscreen |

Schneider |

|

6 |

PLC |

Siemens |

|

7 |

Photoelectric switch |

Omron |

|

8 |

sensor |

Mettler Toledo |

|

9 |

Cylinder and solenoid valve |

Yadek and Festo |

|

10 |

Triple piece |

Yadek |

|

11 |

Level meter |

Shanghai ThinkPay |

|

12 |

Electric control cabinet |

Explosion-proof -- 6 |

2.2.3 Technical parameters of main equipment of automatic packaging system for granular pesticides

It is used to lift granular materials and deliver them to the packaging silo. The conveying speed is variable-frequency regulated, and the material level in the silo controls the start and stop of the elevator.

|

form |

Bucket lift |

|

Lifting capacity (m³/hour) |

10 |

|

Lifting height (m) |

5 |

|

Control method |

frequency conversion |

|

Material |

The hopper is made of engineering plastics, and the rest of the body is made of 304 stainless steel |

|

Power (kW) |

5.5 |

Used for material storage, including high material level monitoring, and a vibrating arch breaking device on the silo wall to assist in unloading.

|

form |

Square silo |

|

Volume |

1m³ |

|

Silo wall thickness |

3mm |

|

composition |

Bin body, flange, bin cover, vibration arch breaking device |

|

Material |

304 Stainless Steel |

2.2.3.3.1 Technical parameters

|

form |

Double bucket weighing scale |

|

Feeding method |

Gravity + Vibration |

|

Material |

Main body 304 stainless steel |

|

Gas consumption |

~0.1Nm³ / min |

|

power |

0.5 k W |

|

Single machine weighing apacity |

≥ 500 Times / hour |

|

Set weighing value |

Net weight 10 kg/ time |

|

Measuring accuracy |

±0.2-0.3% |

|

|

The weighing scale is composed of weighing system mechanical parts, sensors and weighing control instrument system. The material enters the feeding mechanism from the distribution hopper, and then enters the weighing hopper through the arc door. The weighing meter of the weighing sensor connected to the weighing hopper sends a weight change signal, and the weighing meter controls the arc door feeding according to the preset value. When the weighing is completed, the weighing hopper door opens, and the material enters the packaging machine through the buffer filling hopper.

It has functions such as multi-level feeding, automatic peeling, automatic zero point tracking, etc.

With power failure protection and data not lost during power failure;

It has counting and remote transmission functions. It is required to have clear and stable display and be able to work normally under general electromechanical interference;

Feeding method : gravity + vibration;

The whole process of feeding, weighing and unloading is automatically controlled and self-locking;

The weighing box adopts a frame structure, which is overall stable and well sealed. The sensor is fixed on the weighing box frame and has an independent cover to prevent dust and collision. It is equipped with two dust removal interfaces and breathing holes;

The discharge door of the weighing hopper adopts a double-opening bottom door. The discharge speed is fast.

All doors on the scale body are well sealed , and there is no large amount of dust leakage;

The main parts are all made of 304 stainless steel.

This unit is suitable for automatic bag loading and consists of a bag loading robot, a bag clamping and unloading device, a bag holding and pushing device, a bag opening guiding device, a vacuum system and a control system.

1). Wide adaptability to packaging bags. Manual delivery of bags is sufficient, automatic bag taking, pre-opening, the bag loading robot inserts the knife into the bag opening, and at the same time, the air grippers on both sides clamp the two sides of the bag opening, and finally the bag is loaded.

2). The bagging robot arm is driven by a servo motor. Compared with the pneumatic robots of most other manufacturers, it has the advantages of fast speed, stable bagging, no impact, and long service life.

3). Two proximity switches are installed at the bag opening of the bag clamping device to detect whether the bag opening is completely clamped and whether the bag opening is completely opened. This ensures that the packaging machine does not make misjudgments and does not spill materials on the ground, improves the packaging machine's efficiency and on-site working environment, and automatically removes unfastened packaging bags.

4). The parameters of the packaging machine are set on the touch screen. The human-machine friendly touch screen operation interface can fully monitor the operating status of the entire machine.

5) All control components and execution components of the packaging machine are listed products, which can ensure the long-term, stable and reliable operation of the equipment.

|

Bagging capacity |

>500 bags / hour |

|

Inline packaging capabilities |

≥450 bags/hour |

|

Control method |

Programmable Logic Controller ( PLC ) |

|

Set weighing value |

Net weight 10 kg/ bag |

|

Gas consumption |

~ 0.5-0.7Mpa 0.5N m³ / min |

|

power supply |

AC 380V 50Hz ~ 8kw |

The automatic bag sewing machine adopts photoelectric control, which can automatically and continuously complete the folding, sewing, and braid cutting of kraft paper or plastic woven bags. Its air supply system can cut the braid and lubricate with oil mist. The height of the machine can be adjusted according to the size of the bag, and it has the function of automatic detection and shutdown of broken thread.

|

model |

GS-9C CP4900 |

|

Suture head height |

720-1220mm (from ground to needle) |

|

power |

0.75kw (depending on conveying speed) |

|

Start-Stop |

Photoelectric switch |

|

Stitch width |

7-10.5mm (standard setting 10mm) |

|

Stitch type |

Single needle, double stitch chain stitch (single stitch needs to be customized) |

|

Disconnector Type |

Cylinder driven cut-off |

|

Gas consumption |

~0.5-0.7MPa 3m³/h |

|

Lubrication system |

Automatic oil bath system |

|

Sutures |

Synthetic or cotton thread, 3 x 3 strands |

|

Material |

Main material: Carbon steel sprayed |

The machine is a belt conveyor with variable speed and adjustable conveying speed so that the conveyor speed can match the speed of the bag guide mechanism, folding machine and sewing machine.

|

form |

Belt conveyor |

|

Conveyor length |

4000*400*400-500mm |

|

Conveyor speed (adjustable by frequency conversion) |

0~20 m/min |

|

Material |

Main body material 304 stainless steel |

The user's weighing scale silo is fixed, size: 2600*2000*2800mm; material is 304 stainless steel

Terms & Conditions

1. Delivery time: 60 working days (from the date of receipt of deposit).

2. Payment term:100% with a wire transfer(T/T)is required, the terms are 50% with order, 50% balance before shipment.

3. Delivery documents:

(1) .Certificate and quality document.

(2). English installation and maintenance instructions.

4.

Package Term: Non--fumigation wooden case, suitable

for sea & air transport.

5.Warranty term:Belt not included, all parts in normal use are guaranteed for 12 months (from the date of installation).

6. Requirements for public utility works (air compressor1s3, feed pumps, etc.) : equipment loading and unloading and installation of necessary instruments, installation of foundation embeddings, installation of electricity, gas and water inlet lines required for equipment operation shall be carried out by the buyer.

(1) The buyer shall connect the power supply to the Seller's equipment, and there must be a ground wire to ensure safety.

(2). Power supply: AC 380V±5%,50HZ, 3P or AC 220v± 5%50Hz, 2P. (Voltage can be customized)

7.

After--sales service terms:

The first time’s service is provided by the seller, during the installing and test running, buyer will provide the accommodations and foods, visa, bi--way air tickets. Salary is USD150/day/person.

8. The above quotation is valid for 60 days.

Take a screenshot and recognize the QR code

MGM Machinery