86-139-1681-7899

Belonging category: Lab Machine

Product Introduction: I. BasicWorking Principle and Application:1. Basic Working PrincipleAiris filtered and heated, then enters the granulation chamber through the airflowdistribution plate, causing the powder to suspend and form a fluidized statedue to the combined actio…

86-139-1681-7899

86-139-1681-7899 I. Basic Working Principle and Application:

1. Basic Working Principle

Air is filtered and heated, then enters the granulation chamber through the airflow distribution plate, causing the powder to suspend and form a fluidized state due to the combined action of airflow and gravity. Compressed air and binder enter the nozzle through their respective pipelines, and the binder is atomized into fine droplets at the nozzle, sprayed onto the fluidized powder to form granules. During this process, the left and right exhaust valves and cylinders periodically alternate to clean the powder adsorbed on the collection bag, allowing it to fall back into the granulation chamber, thus completing mixing, granulation, coating, and drying operations.

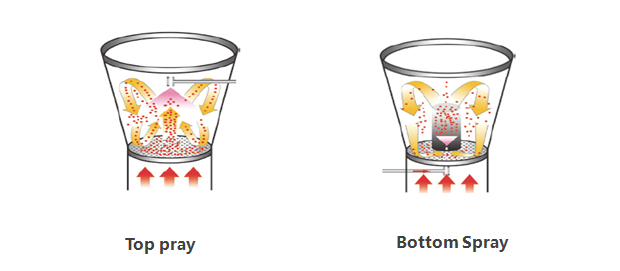

1.1Top Spray: Combines fluidization and airflow transportation. The material in the material tank is pushed upward by the airflow from below, enters the expansion chamber, and is bonded by the slurry. Due to the increase in the diameter of the expansion chamber, the flow velocity decreases, and the fluidization state weakens. The material falls back into the material tank due to gravity, forming a reciprocating flow state from the material tank to the expansion chamber. Its characteristics are: reverse spray, long droplet travel.

1.2 Bottom Spray: Combines fluidization and airflow transportation. Forms a central rising zone and a peripheral fluidization zone. The material in the central zone is pushed upward by the airflow, moves to the expansion chamber to form the rising zone, and falls into the peripheral zone when gravity overcomes the gradually weakening thrust, forming a reciprocating flow state from the center to the periphery, changing random fluidization into regular flow. Its characteristics are: co-directional spray, nozzle buried in the material, short droplet travel; high probability of granules passing through the spray mist; high density of granules in the spray area.

2. Application

This equipment is suitable for mixing, granulating, coating and drying of powder materials. It is widely used in the fields of pharmacy, food, chemical industry, agriculture, forestry, etc. It is the granulating, drying and coating equipment widely used in the international market at present. Because of its different characteristics, it has its own focus in the application.

2.1 Top spraying: granulation and drying Suitable for heat-sensitive materials, high efficiency and uniform drying; granulation: quick dissolution, low hardness, low bulk density, wide particle size distribution, fluffy and porous, good fluidity, easy to disintegrate and dissolve; coating: coloring, masking taste, moisture-proofing and improving appearance.

2.2Bottom spraying: Coating Coating of polymerized materials with water solvent or organic solvent in ordinary film; less adhesion of materials, less evaporation of solvent, suitable for coating of organic solution, slow-release or controlled-release coating, enteric coating, coating of microfine particles, and wrapping dressing layer of active drugs.

The composition of the equipment, the main structure and materials

1.Equipment Composition

This machine is an experimental model, and the structure is in the form of single machine structure. The whole machine consists of modular process cylinder, chassis, atomization system, control system components.

1.1 Host cylinder: capture chamber, diffusion chamber, top spray container, bottom spray container seat.

1.2 Chassis: air inlet filtration system, heating system, induced anechoic system, connecting pipeline, electronic control board located in the chassis, touch-screen operating panel.

1.3 atomization system: liquid spray gun, peristaltic pump.

1.4 Control system: PLC programmable controller, complete sets of electrical appliances, pneumatic components, touch screen

2、Main structure and material

2.1 Each modularized container can be interchanged according to the process needs.

2.2 Top spray container: equipped with atomizer fast mounting seat, observation sight glass, conical structure, material: SS304.

2.3 Bottom spray container: the atomizer is installed in the center of the airflow distribution board on the bed and sprayed upward, and the container has a built-in deflector.

Material: SS304.

2.4 Capture chamber: pneumatic bag cleaning mechanism, material: SUS304; filter cloth CCP anti-static cloth.

2.5 Chassis: welded from steel, covered with stainless steel plate, containing mechanical and electrical control components, Material: A3/SUS304.

2.6 atomization system: spray gun using two-fluid spray gun, material: SUS304, liquid supply pump for constant flow peristaltic pump

2.7 Air filtration: primary and secondary filtration, material: SUS304, CCP cloth.

2.8 Heater: heat exchange adopts electric heating method, material: SUS304.

2.9 Fan: air pressure and air volume are adjusted by frequency conversion, which can accurately and effectively control the fluidization state.

2.10 Control system: PLC programmable controller, complete sets of electrical appliances, pneumatic components, touch screen set in the chassis panel.

Main performance characteristics

1. Compact structure, beautiful appearance, easy to clean and maintain.

2. Modularized structure form, a machine with a variety of functions.

3. The fluidized bed of the air distribution sieve plate opening shape, distribution status, opening rate of the elaborate design, so that the air distribution has been greatly improved, prompting the material according to the needs of the process and full or orderly fluidization, improve the adaptability of the equipment to the material varieties.

4. The host adopts the air top sealing mechanism to ensure the sealing effect, to avoid the failure to remove the adsorbed powder on the catch bag due to leakage, resulting in air duct obstruction, destroying the state of fluidization, which leads to an increase in the content of fine powder, or unable to complete the process operation (bed collapse phenomenon).

5. The atomizer is easy to install and disassemble, with good atomization effect, which is conducive to the needs of the granulation process.

6. Control system: reasonable configuration according to the needs of the system. PLC programmable control, man-machine interface operating system, can set and online adjustment process operating parameters and display equipment operation, actual work parameters. Fan frequency adjustment, can accurately and effectively control the fluidization state, reduce operating costs, reliability, operability and maintainability, simple, intuitive, easy to grasp.

Technical Parameters

|

Model Item |

LDP-1.5 |

|

Production capacity (Kg/batch) |

1.5 |

|

Material yield (%) |

≥99 |

|

Finished product moisture content (%) |

Up to 5-0.5 |

|

Working volume (L) |

7 |

|

Cylinder diameter (mm) |

Φ300 |

|

Blower power(Kw) |

3 |

|

Electric heating power(kw) |

3 |

|

Compressed air pressure (Mpa) |

0.4-0.6 |

|

Compressed air consumption (m3/min) |

0.6 |

|

Operating temperature (℃) |

Normal temperature - 100℃adjustable |

|

Product main dimensions (L×W×H mm) |

1300mm*1000*2562 |

V. Configuration

|

Name |

Material |

Specification |

Remarks |

|

|

intake system |

Air inlet duct |

SS304 |

δ=1.5/2 |

|

|

Primary filter |

Stainless steel |

Matching |

Grade G4 |

|

|

Middle Efficiency Filter |

Fiber Cloth |

Matching |

Grade FB8 |

|

|

High temperature and high efficiency filter |

|

Matching |

Grade H13 |

|

|

Air inlet system heating box |

SS304 |

δ=1.5/2 |

Double-layer heat preservation and insulation |

|

|

Electric heater |

SS304 |

3kw |

For heating |

|

|

Air inlet temperature sensor |

SS304 |

PT100 |

Online detection of the inlet air temperature display and automatic control of the inlet air temperature, control on the PLC |

|

|

bottom cylinder |

Ejector section |

SS304 |

δ=3mm |

|

|

Lifting cylinders |

|

Sc63*100 |

PLC control |

|

|

sewerage equipment |

SS304 |

Φ22 |

|

|

|

Pneumatic seals |

silicone rubber |

Matching |

PLC control for jacking seals |

|

|

drying bed |

Hopper |

SS304 |

δ=3mm |

|

|

Flanges |

SS304 |

δ=18mm |

|

|

|

Material temperature sensor |

|

PT100 |

Online monitoring of material temperature |

|

|

Sight glass |

reinforced glass |

Matching |

Online observation of material production |

|

|

Explosion proof sampler |

SS304 |

|

Online monitoring of material results |

|

|

Center cylinder (diffusion chamber) |

Cylinder |

SS304 |

δ=3mm |

|

|

Flange |

SS304 |

δ=18mm |

|

|

|

Sight glass |

reinforced glass |

|

|

|

|

Spotlights |

|

Matching |

|

|

|

head cylinder |

Head |

SS304 |

δ=3mm |

|

|

Soot cleaning cylinder |

|

Sc32*150 |

Alternating left and right ash cleaning, PLC control |

|

|

Damper cylinder |

|

Sc32*100 |

2, according to the setting, the left and right alternately closed, realize the bag in the state of no convection cleaning dust |

|

|

Bag filter |

CCP Fabric Antistatic |

2set |

Capture the dust and make it fall into the fluidized bed to continue granulation. |

|

|

Exhaust air temperature sensor |

SS304 |

PT100 |

Detect the temperature of inlet air |

|

|

exhaust system |

Exhaust duct |

SS304 |

Φ159δ=1.5mm |

For exhaust gas discharge |

|

Exhaust air valve |

|

Φ120 |

|

|

|

Induced draft fan |

|

3kw |

PLC frequency conversion control |

|

|

Frequency converter |

|

3kw |

Frequency conversion adjustment of air volume |

|

|

peristaltic pump |

|

BT100mm/1515 BT100mm/1515 single tube |

|

|

|

Peristaltic Pump Silicone Tubing |

Rubber |

16 # |

|

|

|

Pneumatic Components |

Pressure Regulators |

AR-2000 |

Regulating compressed air pressure |

|

|

调压表 Regulator |

AR-2000 |

Manual pressure reducing valve to adjust the atomization pressure |

||

|

Oil-water separator |

AR-2000 |

Adjustment of the pressure level Separates water and oil from compressed air |

||

|

Ejector Cylinder |

Sc63*100 |

PLC control |

||

|

Dampers cylinder |

Sc32*100 |

Realization of bag cleaning under no convection condition |

||

|

Ash cleaning cylinder |

Sc32*150 |

2, alternating left and right cleaning according to the setting, PLC control |

||

|

electronically control |

Control cabinet |

δ=1.5 |

|

|

|

Touch screen |

7 inch |

|

||

|

PLC programmable controller |

LG |

can display all parameters |

||

|

Electrical components |

|

Full set |

||

Take a screenshot and recognize the QR code

MGM Machinery