50ML-1L Automatic Liquid Packing Machine production line

1. Automatic Bottle FeederUSP-1200A

1) Diameter 1200mm, height 950mm;

2) Variable frequency control speed adjustable;

3) Rotary buffering without damaging the bottle;

4) The frequency converter adopts the French Schneider brand.

2. Automatic Piston Filling MachineGZH-12DA1

1) One-click off cylinder cleaning, quick discharge of remaining materials, no liquid accumulation;

2) Servo system closed-loop control, double screw, double linear guide rail transmission, high filling accuracy;

3) Stainless steel edging tempered glass outer frame, sealed well and not fragile

4) The material is thick and does not deform, and it operates stably without vibration;

5) Standard multiple protection devices such as safety doors;

6) Motor dive filling;

7) 360 ° cleaning of the dead corner free material box ensures thorough cleaning of the materials in the cylinder

8) The filling head rises with the liquid level to reduce foam non sticking

9) The touch screen and PLC are both made by German Siemens brand, and the frequency converter is made by French Schneider brand.

3. Automatic Inline Capping MachineFZC-6A

1) Frequency conversion control, simple operation and strong flexibility

2) Pairs of capping-wheel, one by one capping tightly, adjustable handwheel

3) The host includes an automatic cap sorting system,and a cap hanging system

4) Flexible contact of packaging materials, without damaging the product

5) The PLC adopts the German Siemens brand, and the frequency converter adopts the French Schneider brand.

4. Cap ElevatorUSG-150-A

1) 304 stainless steel main frame

2) Automatic control of frequency converter

3) Automatically coordinate with the capping machine without manual intervention

4) The PLC adopts the German Siemens brand, and the frequency converter adopts the French Schneider brand.

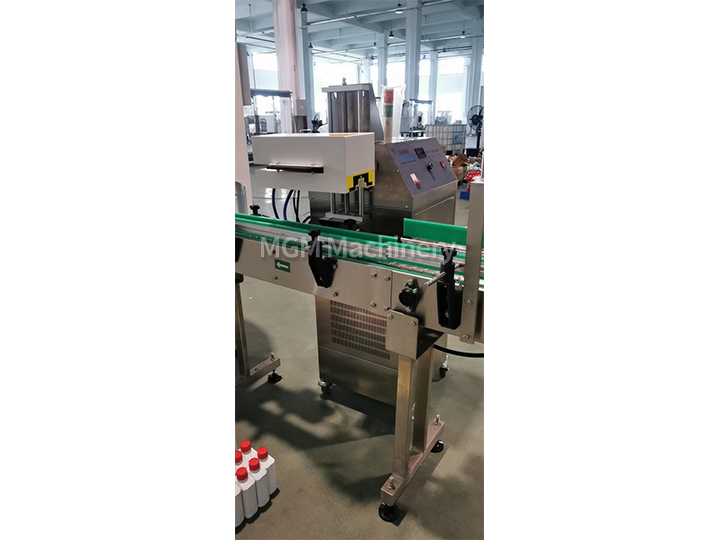

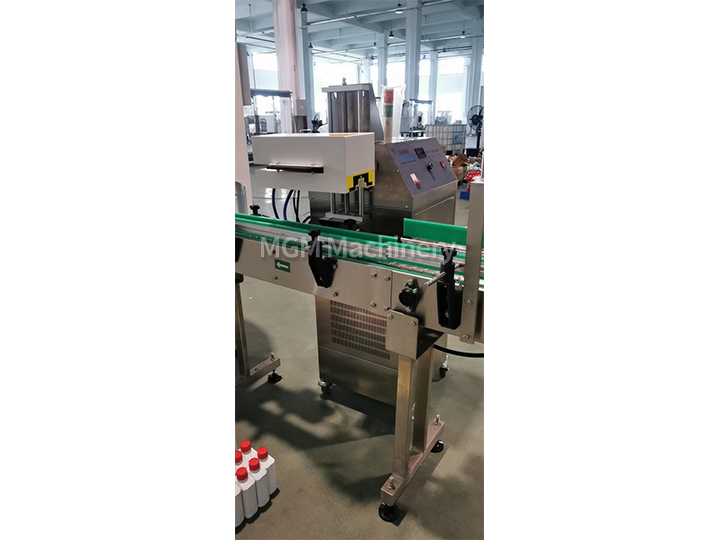

5. Automatic Induction SealerLB-6000J

1) The multi-directional three-dimensional heating mode of the sensing head makes the sealing effect more ideal;

2) Start up without preheating, easy to operate and easy to maintain;

3) Unique switch power supply design ensures constant power output; Power: 4KW

4) Water cooled and air-cooled heat dissipation mode, continuous operation, efficient and high-speed, capable of running for long periods of time all day long;

6. Automatic Labeling Machine TZB-1DY-A

1) Multiple parameter memory storage, one-clickproduction change

2) Servo labeling, high labeling accuracy

3) Wide range, strong compatibility, and high accuracy

4) The designed production capacity is 5000 bottles/hour, effectively meeting production needs, with reservations, and in line with sustainable development.

5) Suitable for 50-1000ml round bottle;

6) The touch screen and PLC are both made by German Siemens brand, and the frequency converter is made by French Schneider brand.

7. Manual Packing Platform UTZ-2000A

1) High and low manual packing design, with bottles on top and boxes on bottom for easy operation

2) Including unpowered roller conveyor, convenient for manual packing and turnover

3) Overall length of 2m, capable of accommodating up to 3 people and packing simultaneously

4) Small platform with bottle buffer, excess bottles can be cached and stacked

5) Over-all 304 stainless steel material

8. Stainless steel Conveyor (SUS304)

1) Chain plate 110 wide conveyor (straight section)

2) Stainless steel > 5mm thick panel

3) The chain plate is made of high-quality stainless steel chain plate material

9. Turning Conveyor

1) Chain plate 110 wide conveyor (turning section)

2) Stainless steel > 5mm thick panel

3) The chain plate is made of high-quality stainless steel chain plate material

10. Dripping tray

Made of 304 stainless-steel, upgraded and deepened

11. Frequency Conversion Motor

Schneider frequency converter control

86-139-1681-7899

86-139-1681-7899