Working principle

Fluidized-bed jet mill is a kind of equipment that realizes ultra-fine grinding of dry materials by high speed jet. It is composed of agrinding nozzle, a grading rotor, a spiral feeder, etc.

The material enters the grinding chamber through the spiral feeder, and the compressed air is sprayed to the grinding chamber at high speed through the specially configured supersonic nozzle, and the material accelerates in the supersonic jet stream, and repeatedly impacts and collides at the intersection of the nozzles to achieve grinding. The crushed material enters the classification chamber with the updraft. Due to the high speed rotation of the classification rotor, the particles are subjected to the centrifugal force generated by the classification rotor and the centripetal force generated by the viscous action of the air flow, that is, the coarse particles above the classification diameter return to the crushing chamber to continue to impact and crush, and the fine particles below the classification diameter enter the cyclone separator with the

air flow, the dust collector is collected, and the gas is discharged by the induced draft fan.

Working characteristics

1、no temperature rise, because the material is crushed in the state of gas expansion, so the body temperature of the crushing chamber the degree control is lower than normal temperature, and can work for along time, and the temperature will not rise.

2、 no pollution, because the material is driven by the air flow closed itself collision and crushing, not into Medium, and can be special treatment of the equipment, so that the material will not be formed during the crushing process Pollution, controlling iron content and other factors.

3、the wear is small, because the crushing effect is the particles themselves collide with each other to crush, high-speed particles and Cylinder wall impact is small, suitable for high hardness materials.

4、for flammable, explosive, easily oxidized materials, the corresponding gas medium can be used for circulation Closed circuit crushing.

5、the company's adjustment of the original air flow mill structure, the output is relative to the original or peerThe same type of air mill 15~30%.

Major Technical Parameters

|

Mode

Parameter

|

BKL-100

|

BKL-200

|

BKL-300

|

BKL-400

|

BKL-600

|

BKL-800

|

|

Parameter(kg/h)

|

0.5~10

|

10~100

|

80~120

|

50~260

|

80~450

|

200~600

|

|

Air consumption(m3/min)

|

3

|

4.5

|

6

|

10

|

20

|

40

|

|

Working Pressure(Mpa)

|

0.75~0.85

|

0.75~0.85

|

0.75~0.85

|

0.75~0.85

|

0.75~0.85

|

0.75~0.85

|

Feed Diameter

|

50~325

|

50~325

|

50~325

|

50~325

|

50~325

|

50~325

|

|

Grinding fineness (um)

|

0.5~75

|

0.5~75

|

0.5~75

|

0.5~75

|

0.5~75

|

0.5~75

|

|

Energy Consumption power(Kw)

|

25

|

40

|

60

|

95

|

188

|

380

|

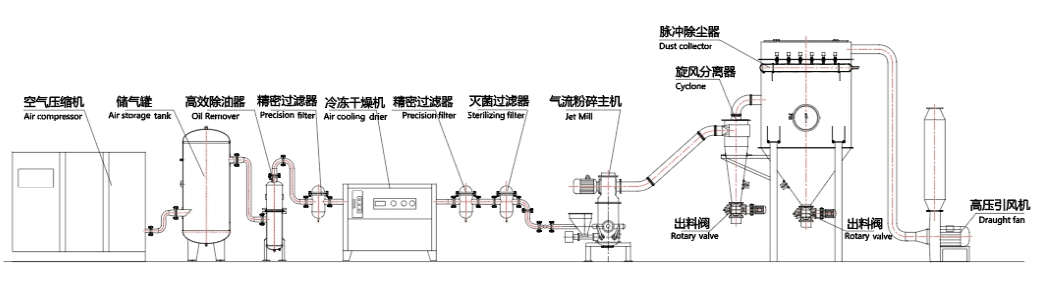

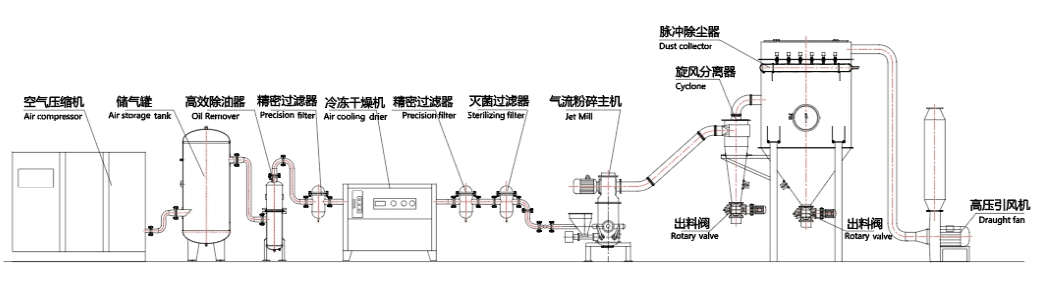

BKL type air flow crushing process

86-139-1681-7899

86-139-1681-7899