86-139-1681-7899

Belonging category: Fluidized Bed Dryer

Product Introduction: Product OverviewSingle cone vacuum dryer is a kind of stirring type closed vacuum dryer. It is heated by a jacketed single cone vacuum closed tank by stirring slurry constantly turning the material, so that the material is uniformly heated, water or s…

86-139-1681-7899

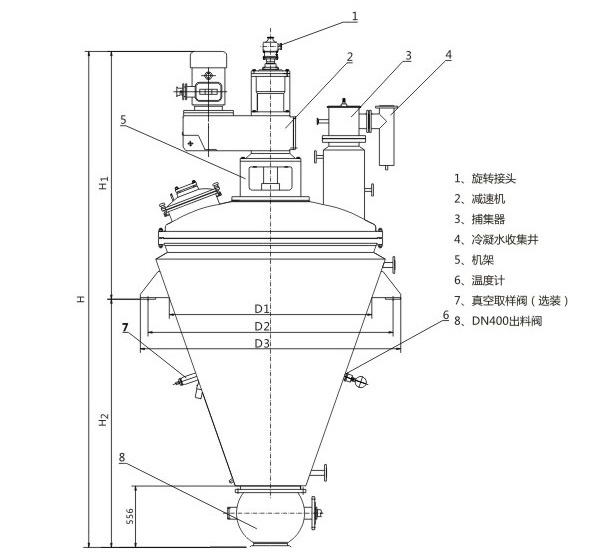

86-139-1681-7899 Single cone vacuum dryer is a kind of stirring type closed vacuum dryer. It is heated by a jacketed single cone vacuum closed tank by stirring slurry constantly turning the material, so that the material is uniformly heated, water or solvent evaporation, to achieve the purpose of material drying. The equipment adopts single cone tank design, sanitary stainless steel manufacturing, simple structure, easy to operate. It is a batch-type gap drying operation, cleaning without dead angle, is a kind of ideal drying equipment in accordance with the GMP requirements of the fine drying package workshop, widely used in pharmaceutical, biological, chemical, food and other industries to get the powder, filter cake, crystals and liquids concentration, drying, evaporation and solvent recovery operation.

The single cone vacuum dryer is provided with a conical screw belt mixing. The whole spiral stirring pulp in the rotation at the same time, the screw belt will continue to lift the material, turning, scraping down, when the material in the tank is mixed evenly, and evenly heated. The evaporated solvent and water vapour are discharged after condensation and recovery by vacuum system after dust removal by filter.

The drying equipment mixing and drying in the same container to complete, improve the production efficiency; the use of jacket heating, reducing the use of energy consumption; the use of vacuum drying form, to ensure the transfer of heat and mass transfer, especially adapted to the drying of heat-sensitive and solvent recovery of powder and granular materials; simple structure, easy to clean, easy to discharging, in line with the GMP norms; to provide a variety of mixing forms and equipment specifications to choose from, and can be carried out in batches of production; can also be cooling, sterilisation, reaction and other operations. Cooling, sterilisation, reaction and other operations can be carried out.

| Model\Item | unit | DZLG-500 | DZLG-750 | DZLG-1000 | DZLG-1250 | DZLG-1500 | DZLG-2000 | DZLG-3000 | DZLG-4000 |

| effective volume | L | 500 | 750 | 1000 | 1250 | 1500 | 2000 | 3000 | 4000 |

| full volume | L | 650 | 800 | 1220 | 1600 | 1900 | 2460 | 3680 | 4890 |

| Heating area | ㎡ | 4.1 | 5.2 | 7.2 | 9.1 | 10.6 | 13 | 19 | 22 |

| Motor power | KW | 11 | 11 | 15 | 15 | 18.5 | 22 | 30 | 37 |

| Net weight of equipment | KG | 1350 | 1850 | 2300 | 2600 | 2900 | 3600 | 4100 | 4450 |

| stirring speed | rpm | 50 | 45 | 40 | 38 | 36 | 36 | 34 | 32 |

| Total height of equipment | m | 3565 | 3720 | 4165 | 4360 | 4590 | 4920 | 5160 | 5520 |

| Height of container | H3 | 1455 | 1610 | 1965 | 2160 | 2300 | 2590 | 2380 | 3160 |

| Headstock Height | H4 | 895 | 995 | 1315 | 1480 | 1630 | 1860 | 1900 | 2240 |

| Inside width of pan | D2 | 1100 | 1200 | 1400 | 1500 | 1600 | 1750 | 2100 | 2100 |

| Mounting Lug Width | D3 | 1270 | 1350 | 1560 | 1720 | 1900 | 2050 | 2400 | 2450 |

Previous: SRQ series heat sink

Next: Jet Mill

Take a screenshot and recognize the QR code

MGM Machinery