Overview

Squeezing granulation is a relatively new dry granulation process for producing composite fertilizers. Extrusion granulation was early used in the field of fertilizers for the granulation of potassium chloride. The granular (1-4mm) potassium chloride required for blending fertilizers (BB fertilizers) is mostly produced by extrusion method. In recent years, the use of extrusion granulation in the production of compound fertilizers has achieved rapid development in China.

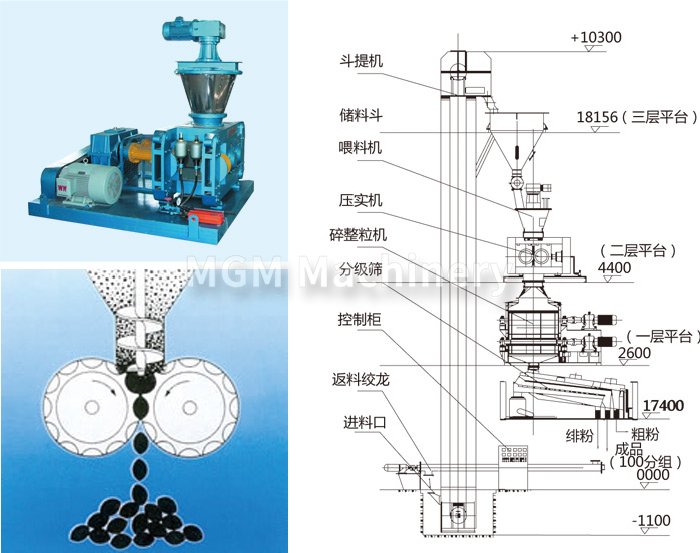

There are two forms of extrusion granulation: roller type and wheel rolling type. Roller type extrusion first presses into large blocks and then breaks them into particles. This device has high capacity, high particle strength, and low energy consumption. Roller type extrusion is widely used abroad. The wheel rolling method is to directly create a groove shaped shape on the surface of the roller, and extrude it into formed particles in one go. When the strength of the product is low, it is sometimes necessary to add adhesive. Suitable for making granular fertilizers such as organic and compound fertilizers.

Operational principle

The process principle of roller extrusion granulation is: dry materials aggregate under pressure to form dense and hard large blocks (cake materials), which is called the extrusion process; The process of crushing and screening the cake material into granules is called granulation. The function of squeezing is to squeeze out the air between particles, and to make the particle spacing close enough to generate attractive forces such as van der Waals forces, adsorption forces, crystal bridges, and embedded connections. The particle strength formed by squeezing granulation mainly relies on the force between molecules.

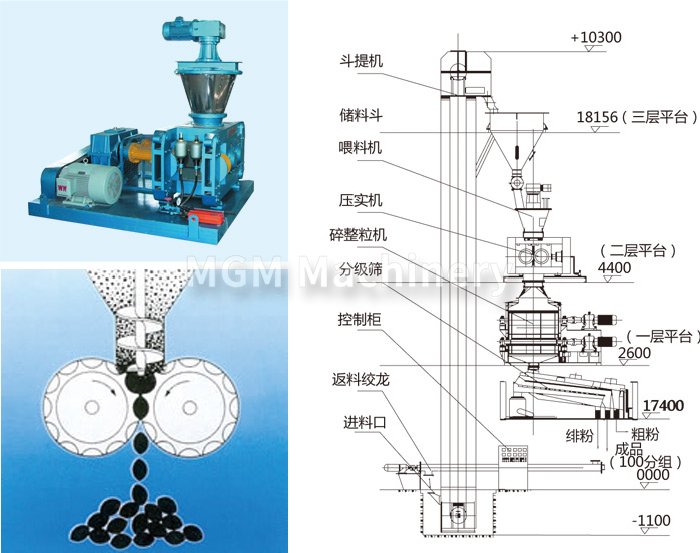

Structural diagram

Technical specifications

|

model

|

Center distance of pressure roller

|

power

|

|

GZL-240

|

240

|

7.5-1.5

|

|

GZL-360

|

360

|

22-45

|

|

GZL-460

|

460

|

37-60

|

|

GZL-580

|

580

|

45-90

|

|

GZL-650

|

650

|

55-200

|

|

GZL-730

|

730

|

90-315

|

86-139-1681-7899

86-139-1681-7899