86-139-1681-7899

Belonging category: Fluidized Bed Dryer

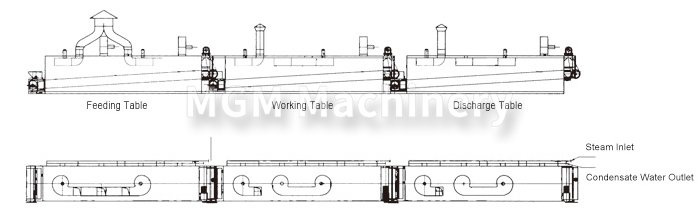

Product Introduction: Working principleThe vegetable dehydration dryer consists of main components such as a feeder, drying bed, heat exchanger, and dehumidification fan. When the dryer is working, the cold air is heated through a heat exchanger and a scientific and reason…

86-139-1681-7899

86-139-1681-7899 The vegetable dehydration dryer consists of main components such as a feeder, drying bed, heat exchanger, and dehumidification fan. When the dryer is working, the cold air is heated through a heat exchanger and a scientific and reasonable circulation method is adopted to ensure that the hot air flows through the dried material on the bed surface for uniform heat and mass exchange. The hot air flow in each unit of the body is circulated by the circulation fan, and then low temperature and high humidity air is discharged, completing the entire drying process smoothly and efficiently.

| model |

DWC1.6-Ⅰ (charging floor) |

DWC1.6-Ⅱ (Intermediate stage) |

DWC1.6-Ⅲ (Discharge table) |

DWC2-Ⅰ (charging floor) |

DWC2-Ⅱ (Intermediate stage) |

DWC2-Ⅲ (Discharge table) |

| Internet broadband(m) | 1.6 | 1.6 | 1.6 | 2 | 2 | 2 |

| Drying section length(m) | 10 | 10 | 8 | 10 | 10 | 8 |

| Paving thickness(mm) | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

| Operating temperature(℃) | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 | 50-150 |

| Heat Exchange Area(m2) | 525 | 398 | 262.5 | 656 | 497 | 327.5 |

| Steam pressure(Mpa) | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 | 0.2-0.8 |

| drying time (h) | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 | 0.2-1.2 |

| Transmission Power(kw) | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 |

| Overall dimensions(m) | 12×1.81×1.9 | 12×1.81×1.9 | 12×1.81×1.9 | 12×2.4×1.92 | 12×2.4×1.92 | 10×2.4×1.92 |

Previous: DW multi-layer belt dryer

Take a screenshot and recognize the QR code

MGM Machinery